Introducing the Innovative Multi Depth Sensor

We are thrilled to introduce our latest innovation, the Multi Depth sensor, a remarkable addition to our product lineup. Product developer Daan Roethof shares insights into the journey of bringing this sensor from concept to mass production.

Key Features of the Multi Depth Sensor

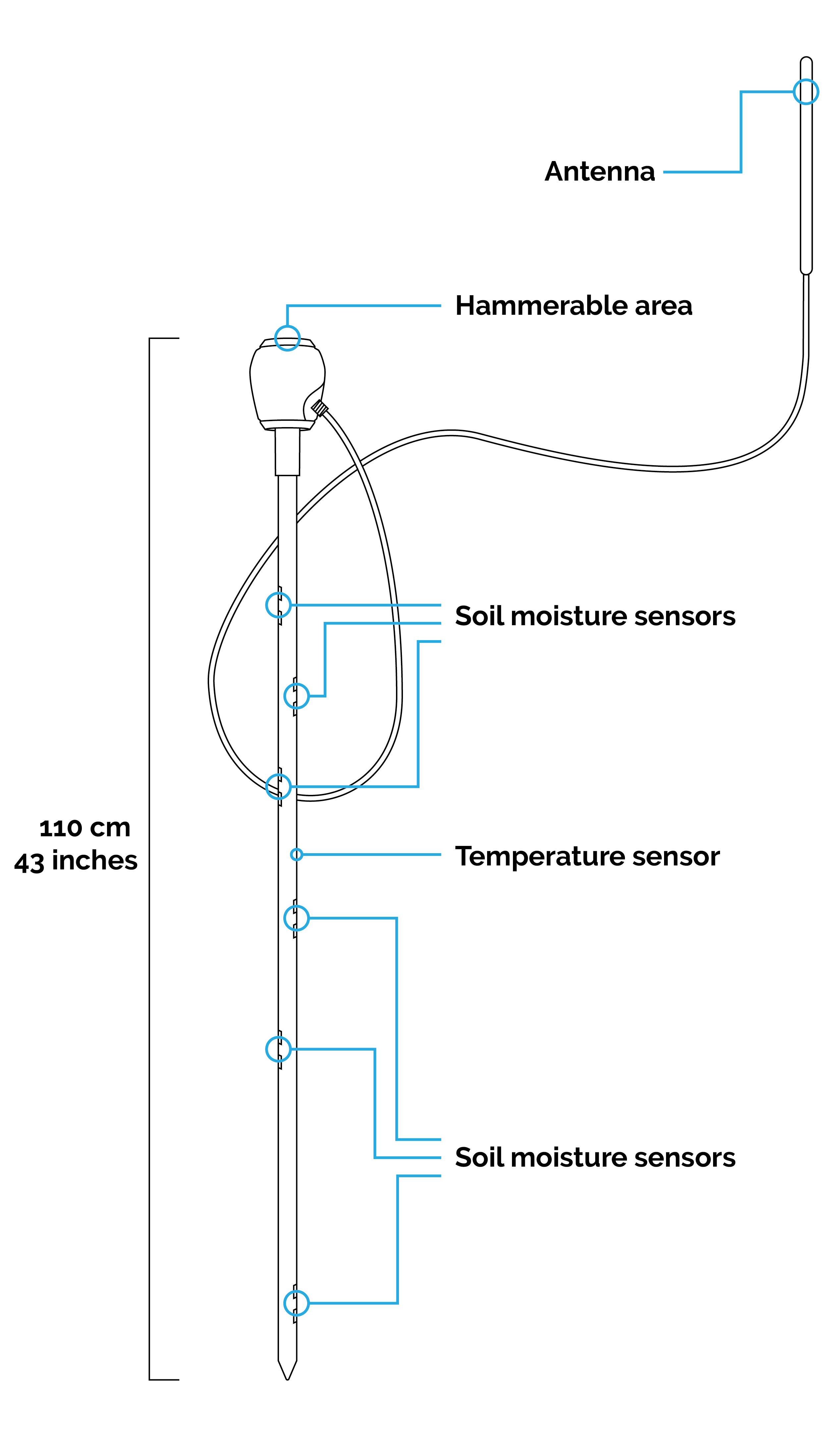

Our new Multi Depth sensor boasts the same robustness as our trusted Single Depth sensor, making it perfect for installation by hammering into the ground. This advanced sensor features six soil moisture sensors, a temperature sensor, and an external antenna for enhanced connectivity. It’s an ideal choice for:

- Crops with Large Canopies: The Multi Depth sensor is designed to cater to crops with extensive canopies, providing accurate moisture data for optimal crop management.

- Complex Soil Horizons: It excels in monitoring soil moisture in areas with intricate soil horizons, offering valuable insights into diverse soil conditions.

- Active Root Zone Monitoring: The sensor allows for continuous soil moisture measurements within the active root zone throughout the entire crop cycle.

Seamless Connectivity and Compatibility

Just like our Single Depth sensors, the Multi Depth sensor communicates via LoRaWAN technology. It’s compatible with all our calibrated soil types, ensuring precise data collection. Access your data for free through our web monitor, dedicated app, or API.

The Journey of the Multi Depth Sensor

The development of the Multi Depth soil moisture sensor has been a lengthy and challenging journey. The need for monitoring crops with varying root lengths, such as corn, throughout the crop cycle was the driving force behind this innovation.

According to Daan Roethof, the product developer, the goal was to create a device with multiple sensors while keeping it simple and robust for easy installation. Several challenges arose during the development process, including material selection and component sizing. Achieving the right balance in the sensor’s design, especially the sensor head and ground pin, was crucial to ensure durability and protection of the electronics.

Over ten design versions and more than 100 prototypes were crafted and rigorously tested in the lab and real-world scenarios. Continuous user feedback played a pivotal role in refining the sensor’s design and performance.

Real-life testing, although time-consuming, was essential for validating the sensor’s functionality through full crop cycles. Waiting for data from extended field testing phases was a part of the journey but contributed significantly to the product’s success.

Daan Roethof, the head of Multi Depth sensor development, collaborated with software developers, mechanical designers, manufacturers, and suppliers to transform the initial idea into a practical and efficient sensor solution.

About Sensoterra

Sensoterra is a pioneering leader in the field of wireless soil moisture sensors, offering cutting-edge IoT soil moisture sensor solutions for smart agriculture. Our state-of-the-art Sensoterra soil moisture sensors are at the forefront of agriculture IoT, providing unparalleled soil moisture monitoring capabilities.

Our commitment to precision agriculture technology allows farmers to make informed decisions, optimize their irrigation systems, and embrace sustainable farming solutions. With Sensoterra, access to real-time soil moisture data is at your fingertips, enabling precise water management and water resource management for your agricultural operations.

Sensoterra, established in 2015, with its headquarters in Houten, The Netherlands, develops water management solutions for agriculture/horticulture, smart city management, and water governance. Sensoterra has over 12,000 sensors in the ground globally, and generates hundreds of thousands of data points for smart water management, daily. Learn more at www.sensoterra.com

Contact for more information, pictures and/or interview requests:

Jessica Nuboer

Marketing & Communications

Sensoterra

Email: [email protected]