Improve vegetable and lettuce irrigation with calibrated soil moisture data, Dynamic EC readings, and zone-based adjustments. Sensoterra supports consistent yield and healthier crops.

Precision irrigation for California lettuces & vegetables

California’s lettuce and vegetable growers operate on tight schedules with little margin for error. Shallow root systems, fast crop cycles, and disease sensitivity mean irrigation must be managed with precision, especially in fields with variable soils or salinity conditions.

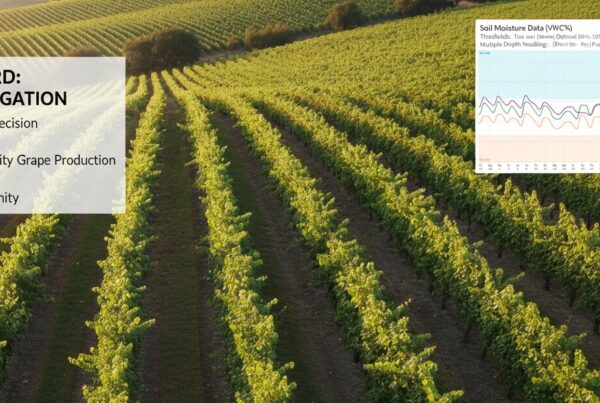

Sensoterra’s soil moisture sensors give growers reliable, calibrated VWC data that helps optimize irrigation timing, protect young plants, and reduce over-application. With long-life wireless sensors and out-of-the-box connectivity, it’s an easy upgrade to improve irrigation performance across large commercial vegetable operations.

Why soil moisture matters for lettuce and vegetable crop

Over-watering in shallow-rooted crops like leaf lettuce, romaine, broccoli, cauliflower, and leafy greens can cause:

- Root disease, chlorosis

- Germination issues

- Patchy emergence

- Nutrient leaching

- Lower uniformity

Under-watering, meanwhile, impacts plant development and harvest timing.

Real-time VWC helps growers maintain moisture in the top 6” – 12”, the critical root zone for these crops.

Dynamic EC: A Key Advantage for Specialty Vegetables

Vegetable producers frequently deal with shifting EC levels in the soil, especially in saline-prone zones, or high-fertility soils. Sensoterra’s Dynamic EC feature automatically adjusts readings once per day based on EC conditions.

You get:

- More accurate VWC measurements

- Better insight into salinity-related issues

- Improved fertigation efficiency

- Better decisions regardless of soil conductivity changes

This means you get two major data types, soil moisture and EC-adjusted accuracy from a single device.

Soil-Type Calibration and Crop Adjustability

Sensoterra sensors are calibrated for the exact soil type in the field, ensuring highly accurate VWC. For vegetables, this is critical because growers often manage multiple soil types in a single ranch. Additionally, the calibration can be fine-tuned for individual crops or cultivars, improving management even further.

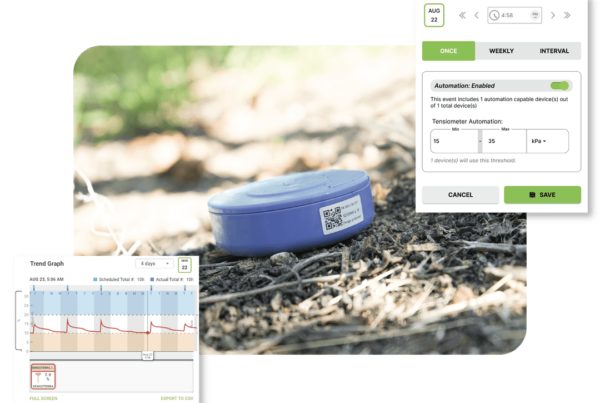

Automation for Vegetable Irrigation Systems

Sensoterra integrates seamlessly with leading automation tools like WiseConn and Jain, as well as controllers from Netafim, Rainbird, and Hunter. This enables:

- Automated on/off irrigation steering

- Zone-specific control for variable soils

- Better fertigation timing

- Reduced over-application for disease-prone crops

Frequently asked questions (FAQ): Smart Irrigation for California Vegetables

1. What is the typical maximum rooting depth targeted for moisture monitoring in California lettuce and vegetable crops?

The effective root zone for shallow-rooted crops like lettuce is typically limited to the top 6 to 12 inches (15 to 30 cm) of the soil. Monitoring must focus on this zone to prevent over-watering below the roots, which causes nutrient leaching and water waste.

2. What are the most common root rot diseases in California lettuce directly caused or exacerbated by over-watering?

Excess soil moisture creates conditions favoring water mold pathogens. Two major root rot diseases are Bottom Rot (Rhizoctonia solani) and Pythium Wilt (Pythium uncinulatum). These pathogens thrive in consistently saturated soil conditions.

3. What is the optimal Volumetric Water Content (VWC) range or Plant Available Water (PAW) threshold that lettuce growers should target during peak growth?

Lettuce has a low tolerance for water stress. Growers generally aim to maintain soil moisture close to Field Capacity (FC), often targeting a VWC that corresponds to a soil matric potential of 20 to 60 kPa (or cbars) to ensure readily available water and consistent growth.

4. How does the timing of irrigation change for lettuce from the seedling stage to the final heading/harvest stage?

**Establishment/Seedling Stage:** Requires frequent, light irrigations to maintain uniform surface moisture. **Rapid Vegetative Growth/Heading Stage:** Requires less frequent but deeper drip irrigation to match the crop’s highest water demand (Evapotranspiration or ET).

5. Why is drip irrigation management essential for uniformity in California vegetable beds, and how do sensors help?

Drip uniformity is challenged by pressure, clogging, and sloping. Sensors help by confirming that all sections of a zone are reaching the target VWC at the same time. Discrepancies indicate poor uniformity or the need for slope-based zoning.

6. Beyond soil moisture (VWC), how does the Dynamic EC feature specifically help manage nutrient leaching in a fertigation program?

The Dynamic EC (Electrical Conductivity) feature tracks salt concentration. If EC levels rise rapidly, the grower knows to apply a leaching fraction (extra water) before the crop is stressed, which is a key part of smart salinity management.

7. How does the shallow rooting nature of lettuce affect the irrigation strategy during hot, windy California days?

The small water reserve in the shallow root zone depletes quickly under high Evapotranspiration (ET) stress. This necessitates shorter, more frequent drip cycles (often 2-3 times per day) to refill the limited reservoir and prevent midday wilting.

8. What role does weather-based scheduling (like CIMIS/ET) play alongside soil moisture sensors for these crops?

Weather-based systems (CIMIS) determine how much water is needed (the amount, ETc). Soil moisture sensors determine when to apply that water by providing the actual, real-time ground truth. Combining them offers the most precise control.

9. In field blocks with variable soil textures (e.g., sandy loam next to clay loam), how should VWC sensors be used to manage irrigation?

The field must be divided into separate irrigation zones based on texture. Sensors in sandy soils (lighter, dry faster) will have lower VWC thresholds and require more frequent, shorter cycles than the heavier, slower-drying clay loam zones.

10. What challenge does crop rotation pose for a fixed sensor network in a vegetable operation, and how is it addressed?

Vegetable ranches use tight rotations, demanding sensors be moved frequently. The wireless, easy-to-install nature of the sensors allows them to be quickly moved and redeployed to the new beds/rows immediately after planting, ensuring continuous data coverage for the next crop cycle.

About Sensoterra

Sensoterra takes the lead in wireless soil moisture sensor technology, offering cutting-edge IoT solutions for smart agriculture. Our state-of-the-art moisture sensors are pioneers in the field of soil moisture monitoring. We are committed to revolutionizing precision agriculture, helping farmers optimize their irrigation systems and promote sustainable farming. With Sensoterra, you gain real-time access to critical soil moisture data, empowering you to manage water resources with precision. Established in 2015 and headquartered in Houten, The Netherlands, Sensoterra develops innovative water management solutions for agriculture, horticulture, smart city management, and water governance. Our global network boasts over 12,000 moisture probes in the ground, generating an abundance of data points daily. Jessica Nuboer Marketing & Communications Sensoterra Email: [email protected]